Automated Material Processing (AMP), comprising industry leaders Kason Corporation and Marion Process Solutions, has recently introduced its TotalClean Clean-in-Place (CIP) systems. These innovative CIP solutions are designed to increase efficiency, safety and profitability across a range of industries including food, pharmaceutical, nutraceutical, chemical, cosmetic, food processing, dairy and brewing, all while meeting validation of FDA, 3A and BPE standards.

The CIP systems employ advanced technology and high-pressure nozzles to thoroughly clean even in challenging and hard-to-reach areas. The automation reduces manual intervention, providing a consistent and repeatable CIP cleaning process compared to traditional methods. Furthermore, the faster cleaning cycles of Marion’s and Kason’s TotalClean CIP systems, which average 30-60 minutes, result in higher profit margins by enabling quicker batch changes and increased product throughput.

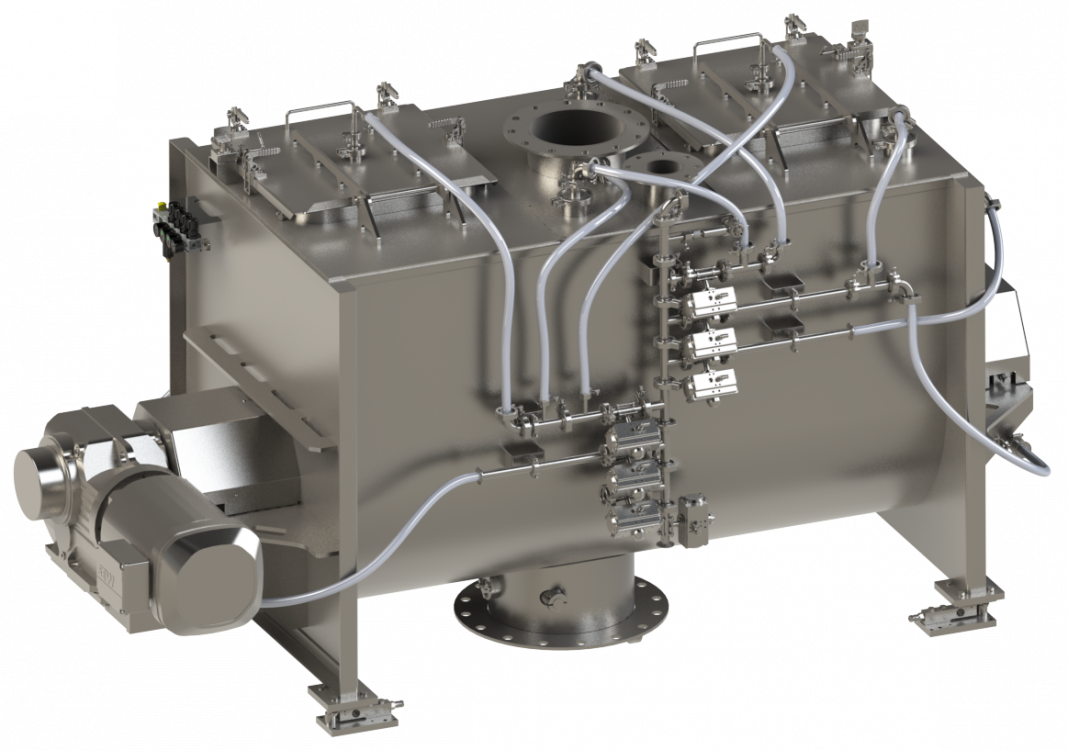

Marion’s TotalClean CIP system stands out for its highly customisable devices and zones, targeting specific areas such as door recesses, inlet ports, discharges and mixer agitators. This customisation ensures comprehensive cleaning coverage, achieving up to 99% wash coverage. Additionally, Marion’s system offers the flexibility of mobile units mounted on a skid or static installations, making it ideal for various facility layouts. Key features include high-pressure/low-flow pumps, pressure and flow control, on-demand hot water, temperature monitoring and control, detergent injection and conductivity-based detergent control. The system also integrates HMI/PLC controls for precise operation, monitoring and verification. Marion’s CIP system can be retrofitted to industrial mixers, blenders and more, ensuring seamless integration into existing processes.

Engineered to clean a wide range of equipment, including centrifugal sifters, vibratory screeners and fluid beds, Kason’s TotalClean CIP system features a compact design. Available as either a mobile skid for added flexibility and versatility or as a static unit, the system allows for easy integration into facilities with limited space without compromising functionality. It also shares several advanced features with Marion’s, such as high-pressure/low-flow pumps, pressure and flow control, on-demand hot water, temperature monitoring and control and detergent injection with conductivity-based control. These features ensure precise management of the cleaning process, enhancing both efficiency and effectiveness. Like Marion’s system, Kason’s CIP system can be retrofitted to any product or vessel, providing flexibility and adaptability for various applications.

The CIP systems offer significant advantages for a wide range of industries. In the food industry, for example, they ensure hygienic processing conditions, prevent cross-contamination and comply with stringent food safety standards. Similarly, in the pharmaceutical sector, the systems maintain strict hygiene standards, prevent contamination and ensure compliance with regulatory requirements. Likewise, the nutraceutical, chemical, cosmetic, food processing, dairy and brewing industries also benefit from these systems in various ways.

“The introduction of AMP’s TotalClean CIP systems represents a significant advancement in industrial cleaning technology,” said AMP’s CEO, Seth Vance. “These systems increase operational efficiency and throughput by maximising machine utilisation and reducing downtime. Additionally, they provide a safer cleaning process with decreased manual intervention and associated risks. Plus, their customisation and retrofit capability allows our customers to seamlessly integrate these advanced solutions into their existing processes on any product or vessel.”

For more information on AMP visit here.