McCain completes acquisition of frozen food producer

Glanbia to acquire Flavor Producers for $300m

Investment house makes £3m follow-on investment in Daily Dose

Investment house IW Capital has made a further £3 million investment into its portfolio company, Daily Dose, the cold-pressed juice and functional drinks business. Daily Dose will use the follow-on investment to fund the next stage of its growth.

With a farm-to-fridge ethos, Daily Dose partners directly with British farmers, taking waste produce that would otherwise be thrown away, and turning it into cold pressed juice sold under its own brand ‘Daily Dose’ and through private label contracts.

Daily Dose was founded in 2016, and, since its inception, has grown rapidly. In the past year, and off the back of IW Capital’s original investment in 2023, the company has delivered another year of growth and has won a number of contracts that have seen it stocked on the shelves of major retailers. It has also acquired a new production facility in Corby, which will enable the scale-up of its juice production operations.

The company is now in a strong position to continue its growth trajectory with its enhanced facilities and machinery. The follow-on investment from IW Capital will be used to facilitate the opening of its Corby site in full, and will also be used to accelerate marketing, sales and key hires.

Isobel Egemole, Investment Director at IW Capital, said: “We’re thrilled to be backing Daily Dose in this follow-on round. As investors in the business, we’ve seen the extraordinary growth that Daily Dose have achieved to date, and we’re excited to be supporting the business for a second time in this next stage of expansion.

“It says a great deal about the partnership we have with Daily Dose, and the confidence that our investors have in the business, that we’re able to provide follow-on funding for this fast growing, exciting company.”

George Hughes-Davies, Founder of Daily Dose, said: “The latest investment from IW Capital comes at an opportune time for Daily Dose as we expand, scale our operations and capitalise on the phenomenal growth we’ve experienced to date.

“We are making a number of significant hires across the business and we are well positioned to continue the company’s fantastic growth trajectory.”

IW Capital was advised by EMW Law. Daily Dose was advised by Wilsons Solicitors LLP.

Bakery manufacturing company acquires artisanal inspired firm

BRIDOR, subsidiary of LE DUFF Group, has acquired PANDRIKS Holding B.V., a company that makes organic and artisanal inspired bakery products.

With this major acquisition, BRIDOR continues its strong global growth and emphasises LE DUFF Group’s commitment to accelerate its growth in the bakery sector.

Founded in the Netherlands in 2012, PANDRIKS makes artisanal inspired bakery products. The company offers traditional bread made with noble ingredients and organic bread under private label (in-store bake-off) and through its own brand, SlooOW (home bake-off).

The two state-of-the-art production facilities in Meppel (Netherlands) and Fulda (Bio Breadness – Germany) allow PANDRIKS to supply the main European retail chains as well as overseas customers.

PANDRIKS has a turnover of €150 million (2023) and 400 employees. Under the BRIDOR umbrella, PANDRIKS will continue its journey with both its brand and values being preserved.

The integration of PANDRIKS will expand the Group’s production capacity and bolster its product portfolio, particularly in the organic bakery market. It will also strengthen the Group’s foothold in North West Europe.

Philippe Morin, Worldwide CEO, BRIDOR, said: “The acquisition of Pandriks is consistent with Bridor’s strategy. It gives us the opportunity to take a leading position on key markets such as the Netherlands and Germany.

“This acquisition will also strengthen our teams with the highly experienced, qualified and motivated people from Pandriks joining Bridor. Pandriks will bring to life the Bridor purpose: ‘Share the bakery cultures of the world’.”

Peter van den Berg, CEO, PANDRIKS, said: “We are excited about the opportunities that lie ahead as we embark on this new chapter with Bridor. Pandriks has grown significantly in recent years and wants to invest in further expansion to optimally serve our clients.

“With LE DUFF Group as our new shareholder, we believe that it is possible to achieve our goals while preserving our unique identity, philosophy and strategy.”

HelloFresh opens its largest European distribution centre

Recipe box company HelloFresh has opened its latest flagship automated production facility in Derby. The site, named ‘The Windmill’, was opened with a ribbon cutting ceremony by UK CEO Adam Park and Pauline Latham OBE MP for Mid Derbyshire.

The new site has created around 300 jobs for the local community to-date with more expected in the coming months as it ramps up production. The automated production lines will allow HelloFresh and Green Chef customers even more choice and ability to personalise their meals.

In keeping with HelloFresh’s commitment to a more sustainable future, The Windmill has been developed in partnership with SmartParc SEGRO Derby, a low-carbon food manufacturing campus in Spondon, Derby, to be one of the most sustainable production facilities in the country.

Features include a rainwater harvesting system, a 22 MVA rooftop solar panel array, and a shared heating and cooling system which recycles heat from refrigeration plants and reuses it to heat water and offices across the estate.

The site achieved an ‘Excellent’ BREEAM rating for its energy efficiency and will derive 100% of its energy from renewable sources. It will also have EV charging spaces, local bus services that are aligned with production times and provide secure bike storage (alongside a cycle-to-work scheme) to further reduce local emissions while supporting its employees.

The expansion of production capability provided by The Windmill supports HelloFresh Group’s ambitions for long-term growth and will act as a launch pad for future growth and innovation for its brands in the UK.

The automation technology will allow for handling of greater product complexity to give customers more recipes to choose from as well as options to further personalise their meals, including options to replace meat for plant-based alternatives or customise portion sizes.

The site will also use best-in-class predictive algorithms and technology to improve inventory management processes, reduce waste, and ultimately deliver ingredients that are fresher than ever.

The Windmill has created around 300 jobs for the local community so far – including production operatives, maintenance engineers, and management roles – with more to come as production ramps up in the coming months.

The Windmill will also boost HelloFresh’s support for local charities like Community Action Derby. Today, HelloFresh donates ingredients for more than 100 meals each week to assist those experiencing food insecurity in the local area.

HelloFresh UK CEO, Adam Park, said: “We are delighted to open our largest and most advanced European distribution centre – The Windmill – here in Derby.

“We have invested for over two years to build our latest automated production technology in Derby, particularly due to its incredibly diverse and skilled talent pool. This site and its cutting-edge technology will allow handling of great complexity in our production to give customers even more choice, while creating hundreds of jobs and opportunities for talented people in the local area to build skills and careers in a growing space.

“Derby’s great connectivity also means we can provide an even better delivery experience for our UK customers with eighty per cent of customers now being within a four-hour drive of where the product is made.

“All-in-all, we are delighted to be in Derby and look forward to contributing to this great community as we partner on an exciting journey of growth and innovation we have planned for HelloFresh and Green Chef in the UK.”

Also present at the opening ceremony were Cllr Baggy Shanker, Paul Simpson, CEO Derby City Council, Jackie Wild, Founder and CEO of SmartParc, Andrew Pilsworth, Chief Of Staff at SEGRO, and Jane Byam Shaw OBE, Co-Founder of the Felix Project.

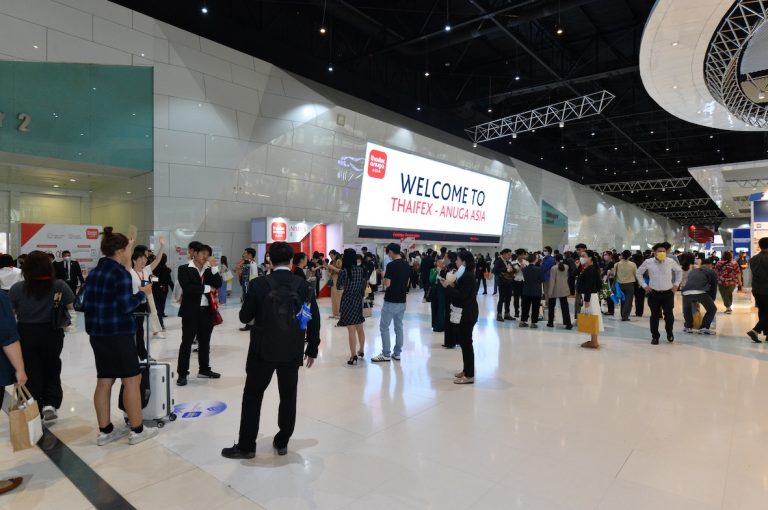

Beyond Food Experience for Success Beyond at THAIFEX – ANUGA ASIA 2024

Registrations now open for London Packaging Week

Established knowledge drives success in challenging cleaning environments

Plant-based product potential soars with the help of membrane filtration technology

VEGATRUCK ‘on the road’ customer training facility 2024 UK tour

- Expert Guidance: Engage with VEGA’s pressure and level experts who will be on hand to provide in-depth training, demonstrations, and answer any questions about the featured product range.

- Product Demonstrations: Experience first-hand the capabilities of VEGA’s cutting-edge products, including the universally adaptable 6X® Non-Contact Level radar tailored to your process needs; discover the low-cost, versatile and resilient level sensors for the Water Industry; take a closer look at the comprehensive line of pressure instruments, with the added excitement of the ‘strong thumb’ challenge; delve into the advantages VEGA provides for the chemical, petrochemical, food, and pharmaceutical industries, and much more…

- Wireless IIoT Solutions: Explore VEGA’s latest battery-powered wireless IIoT radar solutions, offering advanced functionality and ease of integration.

- VEGA Inventory System: Learn about VIS – the innovative software designed to streamline inventory management processes.

- Sensor setup with VEGA Tools App: Join a live demo showcasing instrument adjustment with Bluetooth communications, compatible with all plics® sensors since 2002. With easy to use graphic visualisation of your data, a menu structure identical to PACTware/DTM and back-up/restore functions.