Planted invests in production site in Germany

Planted, the Swiss FoodTech pioneer for plant-based meat made exclusively from clean ingredients, is further investing in capacity expansion with the addition of a...

Finnish biotech company secures funding for food-grade mycoprotein factory

Finnish mycoprotein company Enifer has announced the completion of a funding package that enables it to start constructing a food-grade mycoprotein factory in Kirkkonummi,...

Fairfields Farm scales up with multi-million-pound investment to boost crisp production

Fairfields Farm, the crisp producer based in Wormingford, Essex, is continuing its expansion plans with a major factory investment.

The multi-million-pound upgrade includes the installation...

HEINEKEN expands carbon reduction efforts at breweries with new technical partnerships

HEINEKEN has achieved a new milestone in its journey to Net Zero, signing three additional partners, Arcadis, NIRAS and Royal HaskoningDHV, for its global...

Greenyard acquires plant-based ice cream firm

Greenyard has acquired the Belgian company Crème de la Crème, a food tech expert that develops, manufactures, and sells ice (gelato) products and frozen...

Mixing and dispersion technology specialist ystral builds new validation centre

ystral is investing around 1.8 million euros in a new validation centre at its headquarters in Ballrechten-Dottingen (Germany). The centre will enable the machine...

Flavour systems market grows as demand for natural and customised tastes...

The global flavour systems market is expanding as food and beverage manufacturers respond to rising consumer demand for customised and natural flavours. A new...

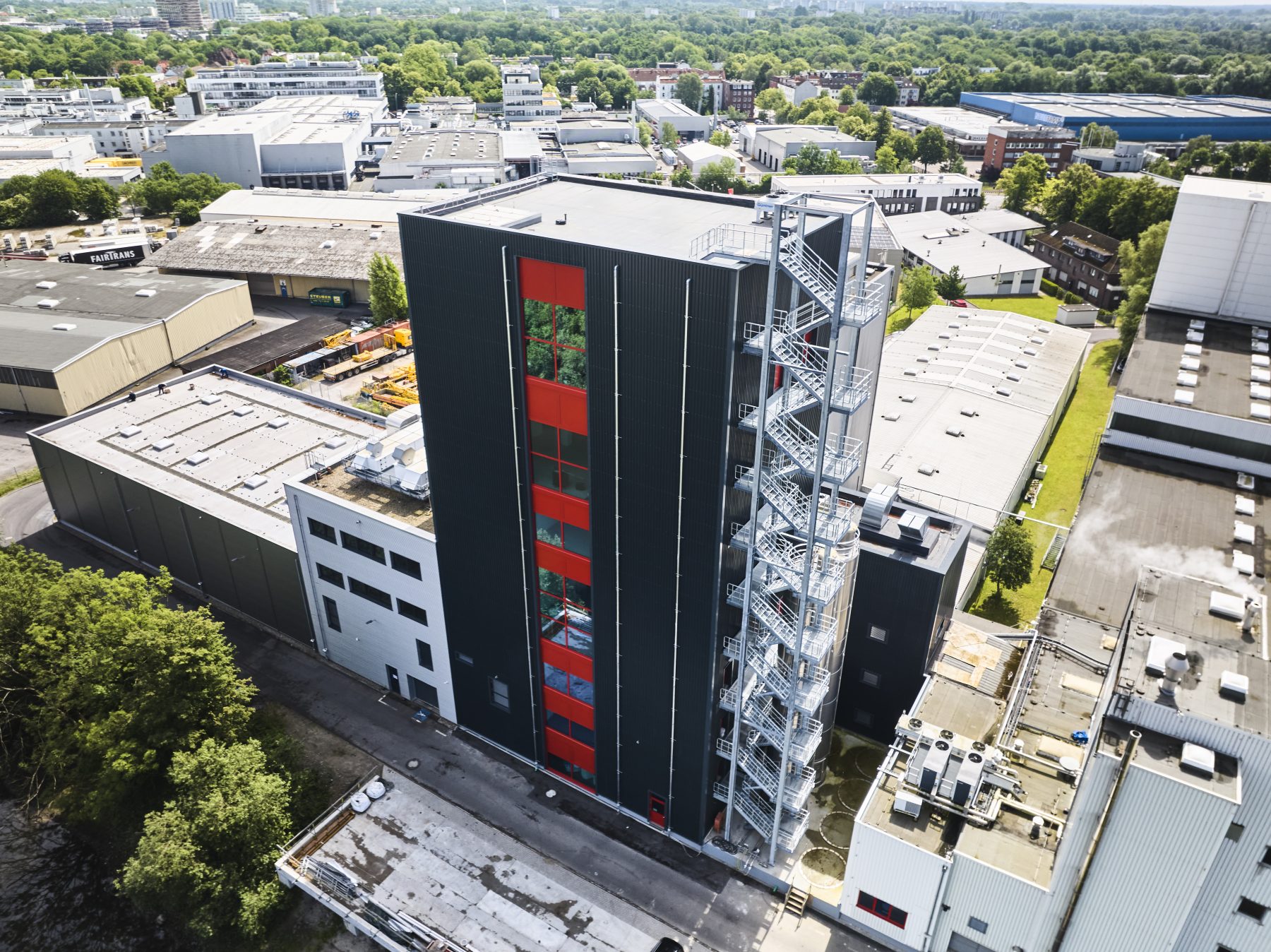

GoodMills Innovation reinforces commitment to plant-based ingredients with new production tower...

GoodMills Innovation’s latest plant project is now operational following completion of a new production tower.

With a multi-million investment, the company is reinforcing its commitment...

Brewers can now use smartphones to detect off-flavours in beer

A new low-cost method developed by researchers allows breweries to detect off-flavours in beer using a smartphone camera and a simple test strip—cutting out...

Caraway Tea files for Chapter 11 bankruptcy

Caraway Tea, a US-based private-label tea manufacturer known for its co-packing services, has filed for Chapter 11 bankruptcy protection. The company declared assets between...